What is it and how does it differ from extrusion

Co-extrusion describes a procedure through which several plastic products are actually pressed with each other coming from different extruders towards type a multi-layered item.

Co-extrusion describes a procedure through which several plastic products are actually pressed with each other coming from different extruders towards type a multi-layered item.

What is it and how does it differ from extrusion

Each product keeps its own setting because of varying viscosities, avoiding all of them coming from blending. This enables various residential or commercial homes to become integrated (like stamina as well as versatility) in a solitary item, creating it practical as well as appropriate for complicated requests.

Distinction in between extrusion as well as co-extrusion

Poland accuses Russia of arson over 2024 shopping centre fire

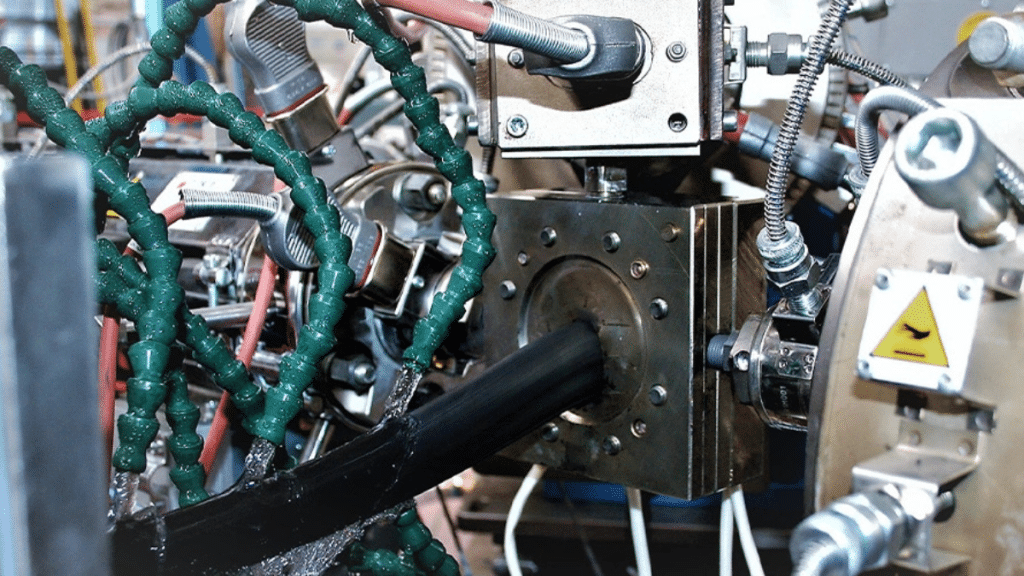

Extrusion as well as carbon monoxide extrusion are actually procedures that are actually frequently mistaken, however each has actually its own very personal distinct functions. In the very initial situation, strong plastic pellets are actually gravity-fed right in to a developing procedure, where compression screws thaw the product. The molten plastic is actually after that pressed with a pass away towards produce a constant form, common of single-material items like tubes, pipelines, as well as sheets.

Co-extrusion, however, utilizes several extruders running at the same time along with various products, as formerly discussed. These products are actually integrated in a pass away towards type a solitary multilayer item.

Nevertheless, the procedure on its own isn't really the just difference—other essential differences consist of:

Kind of product utilized: conventional extrusion utilizes a solitary kind of plastic product, generally such as attire pellets. This creates the procedure easier, along with guide command over the last product's properties—ideal for products that do not need complicated functions. On the other hand, co-extrusion at the same time utilizes several products (various kinds of polymers, practical adhesives, or even obstacle levels). This innovation enables the mix of bodily as well as chemical residential or commercial homes coming from various products right in to a solitary item, providing advanced as well as high-performance solutions;

Requests: extrusion is actually commonly utilized in the manufacturing of attire plastic products like pipelines, stiff accounts, sheets, as well as technological elements where a solitary product structure suffices. Co-extrusion, nevertheless, is actually better for contexts that need multifunctional items. Typical instances consist of multilayer meals product packing, which offers obstacles towards fuel as well as wetness, clinical tubes along with unique coverings, as well as automobile elements that need varying residential or commercial homes in between the surface area as well as the core;

Devices as well as setup: a basic extrusion collection generally needs simply one extruder, a pass away that specifies the product's form, as well as an air conditioning body.

Comments

Post a Comment